A Short History of Ford’s Model A

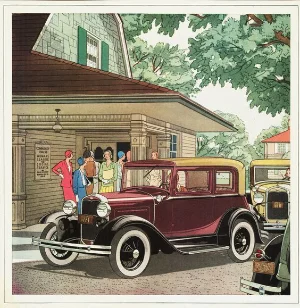

Introduced in December 1927, Ford’s Model A was initially released with six body styles, expanding to more than twenty options ranging from Phaeton to Panel Truck. Ford sold more than 4.8 million Model As before releasing its successors, the Model B and Model 18, in 1932.

Remarkably, at nearly 100 years old, more than 250,000 Model A Fords are estimated to be on the road.

The Model A’s innovation included more than Edsel Ford’s sleek lines and expanded style options. Henry Ford emphasized the Model A’s engine developments in this excerpt from a February 1928 press release:

The new Ford has a remarkable engine

The four-cylinder engine in the new Ford represents a new development in modern automobile engineering. It is unique in design and performance because it develops 40-brake-horse-power at only 2200 revolutions per minute. This means you can do 55 to 65 miles an hour in the new Ford.

Some of the factors which have contributed to this power are the specially designed carburetor, the new hot spot manifold, larger valve diameter, the carbon chrome nickel alloy valves which resist the oxidizing and scaling effect of hot gases, the shape of the combustion chamber which helps to insure higher compression and complete explosion of the gas, the aluminum pistons, the 63-pound fly-wheel, the heavy crankshaft which is statically and dynamically balanced, and build to withstand a twisting stress up to 60,000 in-pounds, the five-bearing camshaft, and the newly designed exhaust system which minimizes back pressure.

Baril Engine’s Ford Model A Services

Baril Engine has extensive experience rebuilding Model A engines, and we are proud to play a role in keeping many of these cars on the road for all of us to enjoy.

While the Ford Model A was a revolutionary engine platform in 1928, there are several ways we improve these engines to produce better reliability and performance while maintaining the engine’s original aesthetics. Baril Engine does the machine work for many customers who do their own assembly work; we offer a package detailed below for those who prefer that we assemble the engine. Regardless of what level of work you would like done, please contact us to discuss your project so we can provide you with a detailed cost estimate and current turnaround timeline.

Disassembly, Cleaning, and Inspection

Thorough cleaning with a high-temperature spray washer and a fair bit of manual labor lays the foundation for a great engine. We disassemble, thoroughly clean, and prepare each engine component for inspection. With each part clean and free of rust and corrosion, we magnaflux the cylinder head, block, and crankshaft to determine if they have any cracks or defects requiring special repairs or replacement.

Engine Block

The original bore size on a Ford Model A is 3.876in. Today, there are several sizes of oversized pistons available. Our package includes boring and honing the cylinders, as needed, to achieve a proper finish and fit to new modernized pistons.

Originally the Model A had main bearings made by pouring babbitt material into the block. While Baril Engine has years of experience pouring babbitt bearing mains, we no longer offer babbitting as an option. Modern main insert bearings have significant advantages over the babbitted bearings.

When converting the Ford Model A engine to modern bearings, it is important to update the block and rotating assembly to accommodate them. Therefore, our Model A engine package includes the following service:

- We machine the block to fit the new modern insert bearings and thrust washers.

The Ford Model A’s original valve train, which is in the engine block, is incompatible with unleaded gas. To update the valve train to allow for unleaded gas and to improve overall reliability we:

- Install new hardened valve seats.

- Remove the old valve guides and replace them with modern one-piece press-in valve guides.

- Install new stainless steel straight stem valves.

- Install new valve springs.

- Machine the lifter bore housing in the block and install new adjustable tappets/lifters, which significantly simplifies adjusting the valves in the future.

Connecting Rods, Pistons & Rings

Originally the Model A had cast iron connecting rods with babbitt bearings. Like the babbitt main bearings in the block, we have rebuilt many engines with re-babbitted connecting rods in the past. However, recently the cost difference between re-babbitting old connecting rods versus buying new forged connecting rods with modern insert bearings has gotten close enough that we no longer use babbitted rods. These new rods eliminate the need to adjust clearances with shims and have superior lubrication, reduced friction, and longer bearing life.

Our Ford Model A engine package includes the following:

- New forged connecting rods with modern bearings

- New modern pistons, pins, and locks

- We weight match connecting rod and piston assembly.

- We custom hone each connecting rod pin bushing to fit a new piston pin.

Cylinder Head

Model A engines often have a different head than the original standard production head. The cylinder heads that we typically see (there are several others) are:

- Model A-6050-A – This is a 1928-1931 standard production cylinder head with a 4.22:1 compression, which is low by most standards. This head has wedged shape combustion chambers that are 242cc to 248cc in volume.

- Model A-6050-B – In 1931, Ford produced this high compression (5.2:1) cylinder head for use in police cars. These heads are designated with a “B” cast into the side of the head, and this head has heart-shaped combustion chambers that are 178cc to 184cc in volume. These Model B heads can be used on a Model A if a Model B style gasket is used. Unfortunately, this original head is known to be prone to cracking.

- Many different aftermarket heads have been available since the 1930s, either as standard production copies or modified “Speed Heads,” seeking to increase the compression ratios and performance.

Regardless of which cylinder head our customer’s engine has, our standard package includes inspecting it for cracks and defects and resurfacing the customer’s cylinder head to remove any warpage and create the proper finish that the new modern gaskets we use require. Our package also included a premium head gasket built using modern technology.

High Compression Cylinder Head Option – An option we offer our customer is upgrading to a new 6:1 high compression head that significantly improves engine performance while maintaining a stock appearance. Dyno tests of engines with this cylinder have produced results of 38.16 HP @ 1400 RPM & 143.15 ft-lbs. of torque and 54.6 HP @ 2500 RPM & 114.7 ft-lbs. of torque.

Crankshaft

As previously noted, when converting the Ford Model A engine to modern bearings, it is important to update the block and rotating assembly to accommodate them. Therefore, our Model A engine package include the following services:

- We machine the crankshaft to fit the new main bearings and thrust washers.

- We machine the crankshaft for a rear main seal.

- We balance the rotating assembly.

Camshaft

The original Model A camshaft (A-6250) produced intake and exhaust lifts of 0.302. However, the lobes wear on the nose over time, which reduces the lift and results in a loss of torque and power. Our standard package includes exchanging the customer’s camshaft for a reground camshaft.

However, if the customer’s camshaft is too worn or damaged, we cannot use it as an exchange cam which requires the customer to buy a new aftermarket cam through us. Please note that new Model A camshafts are currently very difficult to source, and if a customer’s engine requires a new camshaft, it could result in a significant delay.

Also, our standard package includes replacing the camshaft timing gear with a new timing gear.

Model A Oil Leaks

A disclaimer — Even with the improvements we make to our customers’ Model A engines, there are aspects to the Model A that are just a part of running a nearly 100-year-old engine. Specifically, we are referring to the known issue of oil leaks. Please see our article on dealing with Model A oil leaks for tips on resolving them.

Baril Engine’s Warranty for Ford’s Model A and Model B

For Ford Model A and B engines, Baril Engine Rebuilding, Inc excludes all oil leaks, oil leak repairs, or any engine damage resulting from oil leaks from our limited warranty. Please see our limited warranty for the remaining details on our standard warranty coverage.