Baril Engine’s comprehensive range of services, state-of-the-art equipment, and experienced technicians ensure your engine components are in good hands. Our dedicated team of crankshaft machinists are experts at repairing, remanufacturing, and producing custom crankshafts.

Continue reading to learn how we clean and inspect your crank, the difference between grinding and polishing, why we may need to grind your crank, and how we balance your crankshaft.

Cleaning – the foundation of our services!

- Spray Wash: Crankshafts are sprayed with water and an aqueous solution from a jet nozzle within an enclosed system.

- Steelabrator Cleaning: Once degreased, the crank can be bombarded with small pieces of steel shot to clean. Steelabrating is typically reserved for extremely—excessively—dirty or rusty cranks.

- Hand Cleaning: Careful, manual cleaning—this is typically not needed and is reserved for special applications.

- Final Wash: After completing any machine services on your crank, we will do one final wash to prepare for installation. The oil galleys will be cleaned and inspected.

Testing & Inspection

- Crankshaft Liquid Magnifluxing: Using an electrical field and magnetic liquid to check for any cracks in your crankshaft and/or rods.

- Rockwell Hardness Testing: Major and minor load penetration are compared using specialized tools to determine the hardness of the crank. This test is necessary for diesel and high performance engines.

- Stroke Updates and Measuring: This is necessary when replacing your existing crankshaft or creating a custom build, such as a competitive pulling engine. The stroke is the distance the piston travels in the cylinder from top dead center to bottom dead center.

Repair, Grinding, and Polishing

- Crankshaft Grinding: Removal of material from a crankshaft to repair damages or wear with the intent to use oversized bearings, for example, Rods .010″ and Mains .020″ over as shown in the photo.

- Crankshaft Polishing: Polishing the crankshaft removes microscopic burrs, creating the proper surface finish on the components of the crankshaft. Polishing is recommended for all engine overhauls, even those not needing grinding, as it removes minor scoring and defects.

- Crankshaft Straightening: If a bend is located, a crank is straightened using a press to move the centerline within 0.002 inches (0.05mm) TIR.

- Crankshaft Welding & Journal Repair: Badly damaged crank journals can be welded, straightened, stress relieved, and then ground back down to spec.

Reasons to Regrind Before Polishing Your Crankshaft

- Worn, scored, or otherwise damaged crankshafts

- Wear resulting in out-of-roundness due to bearing loads on one side of the shaft

- Significant scoring caused by dirt or metallic particles in the oil

- Defects such as cracks or bends

Balancing

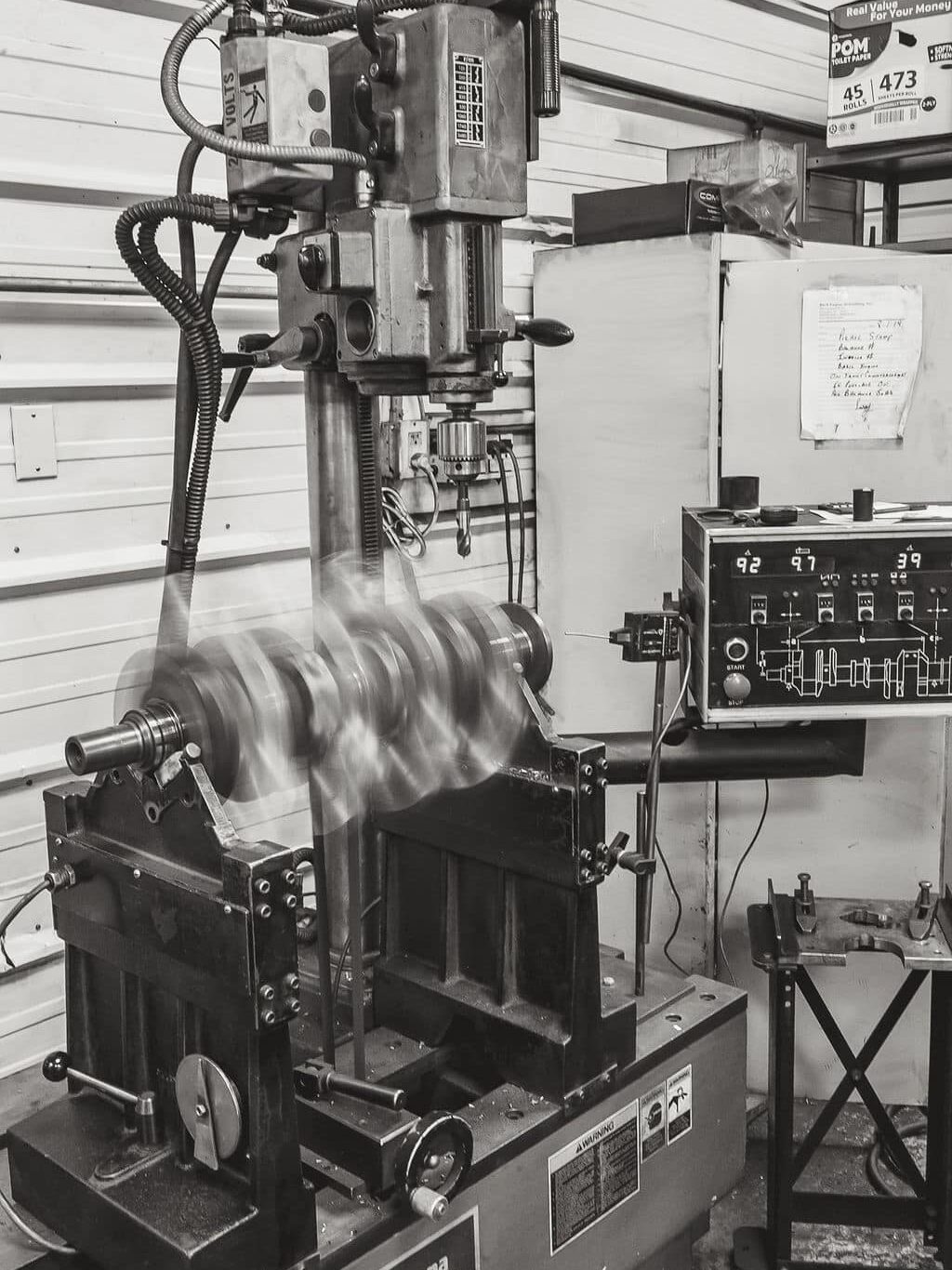

- Crankshaft Balancing: This process ensures crankshaft counterweights properly offset the force provided by the rotation and reciprocation of the piston and rod assembly. A technician spins the crank on a specialized crankshaft balancing machine. When the crankshaft comes to a spot, the balancer will tell the tech where weight needs to be added or removed from the crank.

- Bobweights are used to simulate the installation of pistons and rods on a V-6 or V-8 crank. It is not necessary to install bobweights to balance cranks for inline or opposable cylinders.

- Engine Rotating Assembly Balancing: Externally balanced engines require balancing the entire crankshaft assembly with attached vibration dampers and flywheels (or flexplates).