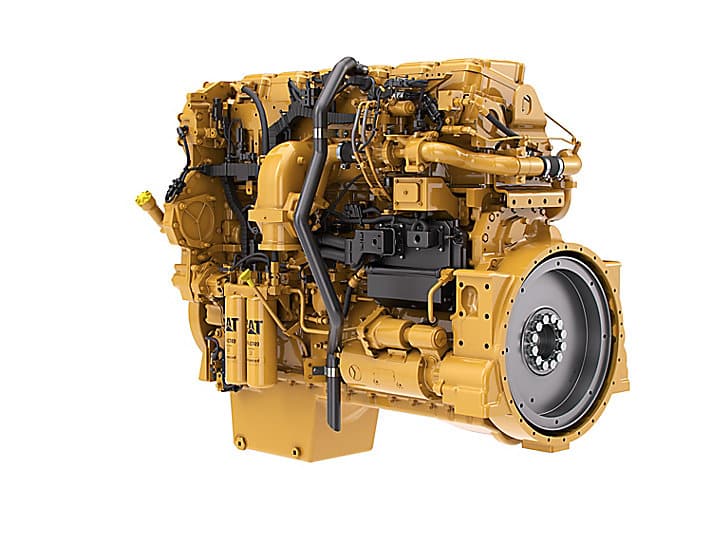

Caterpillar’s C15 engine is a dependable powerhouse known for its durability and efficiency, making it a popular choice in many applications and industries. Whether you rely on your C15 to power your harvester or your Peterbilt, Baril Engine has the experience to keep your CAT purring.

History

Our overview of the C15 must begin with its predecessor, the 3406, and the advancements that led to the versions most commonly in use today. Click each model number to learn more.

3406A

Debuting in 1973, the original 3406 was a fully mechanical 6-cylinder diesel engine with a displacement of 14.6L. This model was produced as both pre-combustion (commonly referred to as pre-cup, 3406A-PC) and direct injection (3406A-DI). Variations of this big-bore engine were used in a wide array of applications, including heavy-duty trucks, construction equipment, and generators.

3406B

Within a few years, CAT released the 3406B. Fully mechanical with direct injection, the most significant difference was that the injector pump location was changed from the 3406A. CAT built this version with different specifications for many applications, including construction equipment and heavy-duty trucks.

3406C

CAT began offering the 3406C in 1987. While the most common version was primarily mechanical with an electrically-controlled fuel pump, CAT also built the 3406C with mechanical injection based on the intended application. Like its predecessors, the 3406C had many variations for use in different applications, including construction equipment, heavy-duty trucks, and marine.

3406E

CAT released the fully electronic 3406E in 1993, skipping over the D designation. Considered one of CAT’s most successful engines, the 3406E incorporated several improvements for longevity and efficiency. CAT strengthened the engine block to reduce the risk of cracking and redesigned the cylinder head to eliminate one cause of head gasket failures. These cylinder head changes included an integral air inlet manifold and overhead camshaft. Other improvements include reduced emissions and increased fuel economy to meet the environmental regulations enacted in the mid-90s. This reliable favorite ceased production in 1999, but many are still in use in Peterbilt & Freightliner vehicles, construction equipment, and marine applications.

3406E engine prefixes 5DS and 1MM signify the 15.8L variation, but the majority of 3406Es were 14.6L engines. CAT replaced this larger version with the C-16, engine prefix 7CZ.

C-15

In 1999, CAT released the C-15 (with a hyphen) to replace the 14.6L 3406E. This pre-ACERT version has engine prefixes starting with 6NZ and 9NZ. While many components carried over from the 3406E, the C-15 is approximately 250 pounds lighter and incorporates cylinder head relief slots, upgraded gaskets, and better seals.

C-15 Bridge

The C-15 Bridge, produced 2001-2003, is the transition model between pre-ACERT to ACERT technology. This version has the engine prefix MBN, nicknamed “Much Bad News” due to elevated operating temperatures, excessive fuel consumption, and reduced pull primarily caused by ECM modifications in anticipation of the upcoming emission standards.

C15 ACERT

In 2003, CAT began production of the C15 ACERT to meet the EPA’s updated 2004 & 2007 emission standards for on-highway equipment. Other improvements include a better bottom end and single-piece steel pistons than earlier models’ aluminum skirted pistons. CAT continued to produce the original C-15 for use in off-highway equipment.

C15ACERT engine prefixes:

- EGH – less than 300 built, often considered a trial run.

- BXS – considered the first true ACERTs.

- MXS – often rated the most popular C15 ACERT, this version incorporated one-piece housings for engine brake & VVAs

- NXS – continuation of MXS as Cat needed more serial numbers.

- RKS

- SDP – the final on-highway C15 ACERT

In 2010, CAT ceased engine production for on-highway equipment, focusing on their larger off-highway markets. At this writing, CAT continues manufacturing C15 engines for industrial use, with multiple variations for specific applications and industries.

CAT 3406E & C15 Applications

Baril Engine regularly rebuilds or machines the components of 3406Es and C15s used in Freightliner and Peterbilt vehicles. Whether you need a heavily modified pulling build capable of 4000 horsepower with extreme torque or are seeking to maximize your engine’s reliability & durability, Baril Engine has the expertise to help you achieve your goals.

Other applications include Agriculture, Ag Tractors, Aircraft Ground Support, Bore/Drill Rigs, Chippers/Grinders, Combines/Harvesters, Compactors/Rollers, Compressors, Construction, Cranes, Crushers, Dredgers, Dozers, Excavators, Forestry, General Industrial, Hydraulic Power Units, Irrigation Equipment, Loaders/Forwarders, Material Handling, Mining, Mobile Earthmoving Equipment, Paving Equipment, Pumps, Shovels/Draglines, Surface Hauling Equipment, and Trenchers.

Known issues that we see:

- 3406Es with a 5EK serial number have a known crankshaft breakage problem at journals 1 & 6, believed to be due to the use of a bad casting. Caterpillar has dealt with these defective cranks on an individual basis when reported.

- 3406Es can also have significant oil leaks, most commonly from the rear structures and flywheel housing due to flimsy gaskets. The 3406E can also experience leaking from the oil check holes in the block when the rubber plugs age & harden.

- C15s can develop issues with the head gasket due to the engine block design incorporating liners that rest on the block rather than being pressed into the block. This can lead to sunk liners as their protrusion shrinks, causing wear on the engine block and blown fire rings.

- Another common issue for C15s is leaking at the spacer plate gasket. This typically is a simple fix, but it could become a more significant issue if overlooked. The first warning sign will be tiny oil bubbles pushing out under the spacer plate between the block and head.

- Turbocharger issues will decrease engine performance as they are critical to the C15 design. If bearings fail, the turbo will rub inside the housing, allowing carbon or debris to damage its fins. Signs of turbo damage include weaker engine performance, low power, higher running temperatures, and little to no boost.

Baril Engine’s Complete Engine Packages

Significant differences exist in what one engine rebuilder includes in a “Short Block” or “Long Block” from another engine builder. If you’re comparing quotes for your CAT 3406 or C15, please look at the details, as Baril Engine includes more in our packages than many other engine builders.

Baril Engine offers three levels of engine rebuild packages:

- Short Block (SB): Includes rebuilding the engine’s rotating assembly (block, crankshaft, connecting rods) and installing liners with O-rings, pistons, piston ring sets, piston pins & retainers, rod pin bushings, cam bushings, lower gasket set, main bearing set, rod bearing set, and thrust washer set.

- Long Block (LB): Includes all the work in the SB level and adds a complete rebuild of the cylinder head, installation of the cylinder head, camshaft, lifters, rocker arms, upper gasket set, oil cooler, oil pump, water pump, and thermostat and adjusting of the valves.

- Ready-to-Run (RTR): Includes all the work in the SB and LB levels and adds many or all of the components and parts required for the engine to be ready to run, including the fuel injectors, fuel pump, and turbo(s).

Baril Engine is a custom engine builder, so our engine packages are customized to reflect each engine’s application and specific needs. Therefore, there can be considerable variation in the processes performed, the parts included, and the total cost from one engine project to the next. It is essential that we discuss and document within your estimate your engine’s history, any known issues, previous repairs, and your specific needs and goals. The more information you provide, the better positioned we are to meet your needs and exceed your goals. Please always refer to your written estimate to know what is and is not included in your engine package.

Baril Engine’s Machining, Rebuilding, and Assembly Services

Disassembly and Cleaning

A thorough and quality cleaning the engine components is a time-consuming and labor-intensive job. However, we firmly believe that it is the foundation of our entire process.

Disassembly and Cleaning details

- Disassembly of the engine and all its components.

- Initial cleaning of the components with a high temp spray wash process.

- Remove any remaining carbon or material from the parts using a variety of hand and pneumatic cleaning tools and processes.

Return to top of Machining, Rebuilding, and Assembly Services Section

Cylinder Head

[Available individually or as part of the LB & RTR packages.]

Cylinder Head Inspection details

- Magnaflux the cylinder head to identify any previously undetected cracks. Magnaflux Testing, also known as magnetic particle inspection, uses a magnetic field and an iron oxide powder or solution to identify surface cracks in metals. It is a time-proven and reliable method of identifying external cracks.

- Pressure testing the cylinder head, as the name suggests, uses air or hot water pressure to test the integrity of the internal coolant passages. With this test, we can find cracks in the head’s coolant passages, leaking frost plugs, and other defects that need to be addressed as a part of our rebuild process.

- Inspect the valves for stem wear, straightness, and if they have sufficient margin to allow grinding.

- Inspect the valve guides for wear and proper clearance.

- Inspect valve seats for wear and defects.

- 3406E and above: remove cam bearings from the head.

Cylinder Head Rebuilding Process details

- Resurface (mill) the cylinder head’s deck to ensure it is straight, flat, and has the proper finish.

- Grind the valves or replace as needed.

- Install new valve seats as needed and cut to produce three-angle valve seats.

- Remove & replace valve guides as needed.

- Replace valve springs with new.

- Replace injector tubes.

- 3406E and above: install new cam bearings in the head.

- Assemble the cylinder head and complete the final inspection of the finished head to verify it meets all specifications.

Return to top of Machining, Rebuilding, and Assembly Services Section

Engine Block

[Available individually or as part of a complete engine rebuild package.]

Engine Block Inspection details

- Magnaflux the block to identify any previously undetected cracks.

- Inspect and measure each main journal bore with a dial bore gauge after torquing the main caps on to specification. This inspection allows us to see if any of the main journal bores need to be resized.

- Both CAT 3406E & C15 have a wet-sleeve cylinder liner sealed with an upper deck counterbore. We inspect the block’s counterbore to determine if it needs to be reconditioned.

- Inspect the main housing bores to ensure they are round and true.

- 3406A through 3406C: remove the cam bearings from the blocks.

Engine Block Reconditioning Process details

- Resurface (mill) the block’s top deck to ensure it is straight, flat, and has the proper finish.

- If the main housing bores are out of spec, align bore the block to correct.

- If our inspection revealed that the deck counterbore area needs work, we machine the counterbores and clean up the sealing surface. Generally, the C15 liner protrusion is on the low end of CAT specifications from the factory. So, typically we cut the counterbores and, if necessary, install liner shims to achieve the correct liner protrusion.

- 3406A through 3406C: replace the cam bearings.

Return to top of Machining, Rebuilding, and Assembly Services Section

Connecting Rods

[Available individually or as part of a complete engine rebuild package.]

Connecting Rod Inspection details

- Liquid Magnaflux each of the connecting rods to identify any previously undetected cracks. Any rod found to have a crack or defect is replaced.

Connecting Rod Reconditioning Process details

- Connecting rod piston pin housing bore (small end): The piston pin bushing on the small end of the connecting rod is subject to wear over time. We recondition the piston pin end on each connecting rod by removing and replacing the pin bushing and honing it to fit the new piston pin to achieve the specified clearance.

- Connecting rod crankpin housing bore (big end): If during our inspection a rod’s crankpin housing bore is found to be deformed or worn, we resize the bore by cutting the cap, torquing the cap on to specification, and bore and hone the crankpin bore to specified size and finish.

Return to top of Machining, Rebuilding, and Assembly Services Section

Crankshaft and Camshaft

[Available individually or as part of a complete engine rebuild package.]

Crankshaft and Camshaft Inspection details

- Liquid Magnaflux the crankshaft to identify any previously undetected cracks. Any crankshaft found to have a crack or defect is replaced.

- Inspect and test the journals to verify they meet or exceed the required hardness specification.

- Inspect the crankshaft for straightness and measure the size and profile of each journal to verify they are as specified.

- Inspect the camshaft and determine if it can be reused or needs to be replaced.

Crankshaft Reconditioning Process details

- If required, we grind the crankshaft after we have verified that oversized bearings are available.

- Polish all the crankshaft’s rod and main journals to their required finish.

Return to top of Machining, Rebuilding, and Assembly Services Section

Engine Assembly

[Available as part of a complete engine rebuild package.]

Pre-Assembly Engine Inspection details

- It is the assembling technician’s responsibility to inspect all parts and verify that each meets specification. We trust but verify!

Engine Assembly details

- Our highly experienced engine builders assemble all our engines in our assembly department, which is sealed off from the remainder of our shop.

- Our engine assembly is a process that involves many detailed procedures that are executed in a specific order by our engine builders so that the completed engine meets our performance and reliability standards.

Return to top of Machining, Rebuilding, and Assembly Services Section

Baril Engine’s In-Chassis Services

The CAT 3406E and C15 use wet-sleeve cylinder liners, allowing in-chassis counterbore service at your location. Baril Engine provides deck counterbore cutting with our portable precision equipment throughout Wisconsin and the Upper Peninsula of Michigan. Contact us to learn how we can combine onsite counterbore services with pickup/delivery for your cylinder head rebuild.